Visual Scheduling System & Work Order Workflow Redesign

Client Type: Manufacturing facility with multi-department production workflow

Overview

This manufacturing site struggled with a chaotic work order system—drawings and job packets were dropped into an unorganized pile on the shop floor. Supervisors had to abandon their stations, dig through stacks, and manually guess priorities based on fragmented communication from office staff. This created production delays, misalignment across departments, and inconsistent throughput.

Challenge

The disorganization caused major inefficiencies:

No visibility into job sequence, lead times, or priority

Frequent disruptions as supervisors searched for the correct work orders

Unclear expectations from management

Lost or damaged paperwork

Production bottlenecks and mismatched timelines across departments

With multiple departments operating on different lead times, keeping work synchronized was nearly impossible. The floor needed structure, clarity, and a future-focused view of incoming work.

Solution

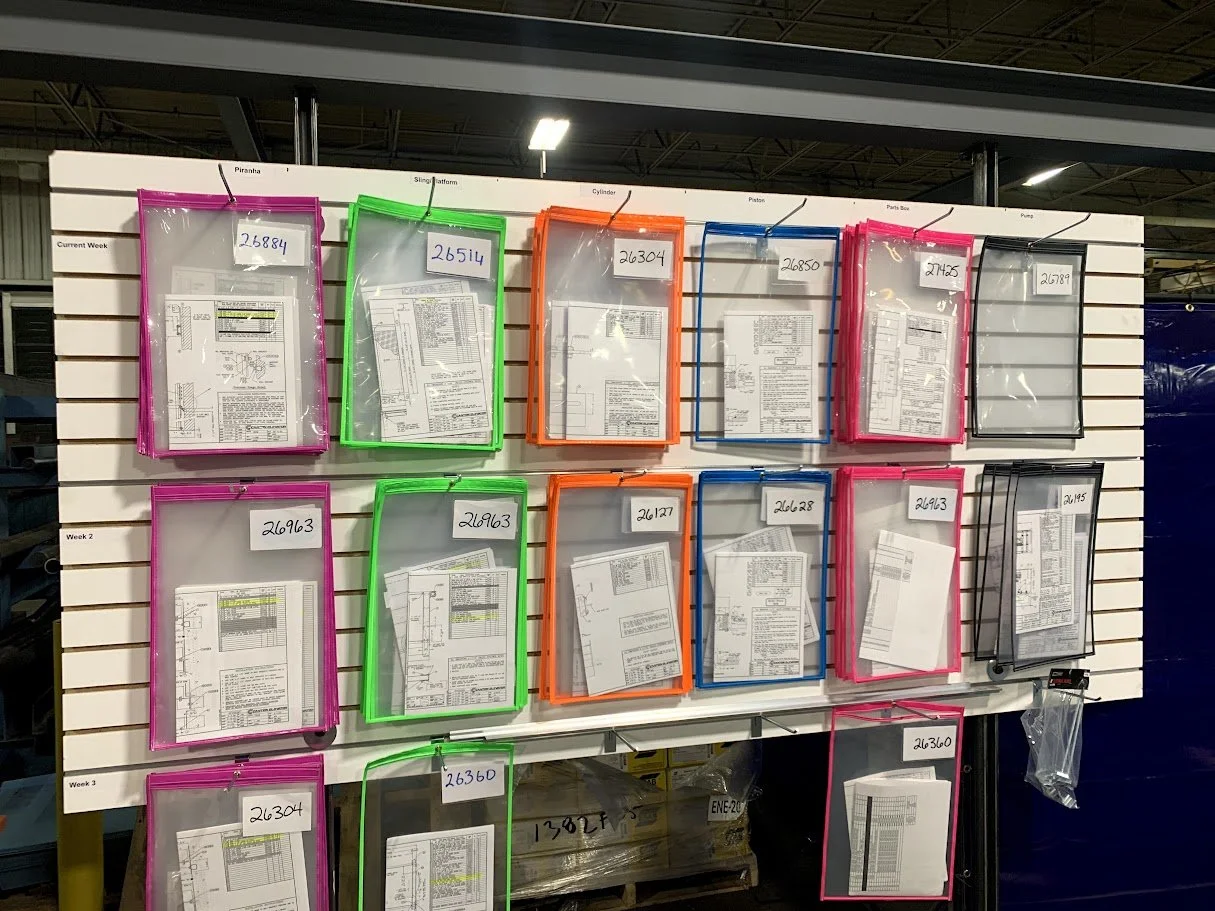

T2P2 Solutions redesigned the entire scheduling and work order process using lean visual management principles—creating the color-coded scheduling wall shown in the reference photo.

Key improvements included:

Color-coded folders by department, providing instant visual recognition

Central slatwall scheduling board, accessible to all supervisors

Three weeks of work orders displayed at all times, ensuring every department could work ahead according to its specific lead time

Time-based sections—Current Week, Week 2, Week 3—to maintain flow and predictability

Priority sequencing from most urgent to least

Build numbers labeled clearly on each packet for quick identification

Job packets bundled with all drawings, BOMs, and instructions

Daily, structured schedule distribution from the Production Manager

Unified workflow, allowing all departments to complete their steps in sync so projects were fully assembled and ready to ship at the same time

This visual and strategic system replaced the chaotic pile with a clear, efficient, and reliable production planning model.

Outcome

The new scheduling system had an immediate and measurable impact:

15% increase in overall production output

Significant reduction in wasted time searching for or sorting work orders

Improved alignment between departments, thanks to the three-week visibility buffer

Faster and more accurate communication between management and supervisors

Reduced errors and missing paperwork due to standardized, color-coded packets

Better sequencing of work, ensuring departments completed tasks in sync

Higher supervisor satisfaction and smoother daily workflows

This transformation created a sustainable, organized, and forward-looking system that helped the facility operate with greater accuracy, speed, and confidence—ultimately improving on-time delivery and customer satisfaction.